Alloy microstructure

In order to be able to assess the local mechanical properties of the processed product, it is necessary to include metallurgical models into the usual simulation software.

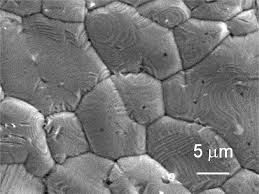

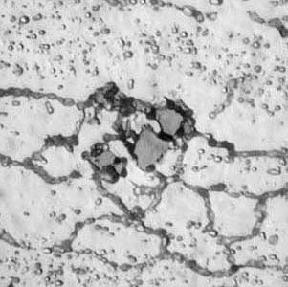

These models enable the user to track the evolution of the grain size and shape during the whole extrusion process according to different quenching types and typical extrusion conditions.

- recrystallization during deformation

- static recrystallization

- grain growth

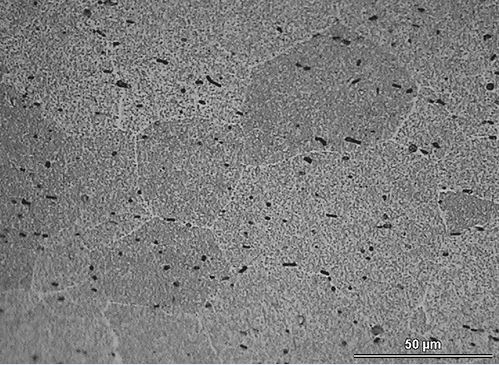

As the relative hardening of the metal during the extrusion process is influenced by the density, settings and motion of existing dislocations in the material lattice, their effect must be quantified and involved in the material constitutive law.

Based on the extensive litterature review and on empirical results, the model that we are developing and testing will be integrated in our 3D simulation tool.

Next topic: Rheology and microstructure